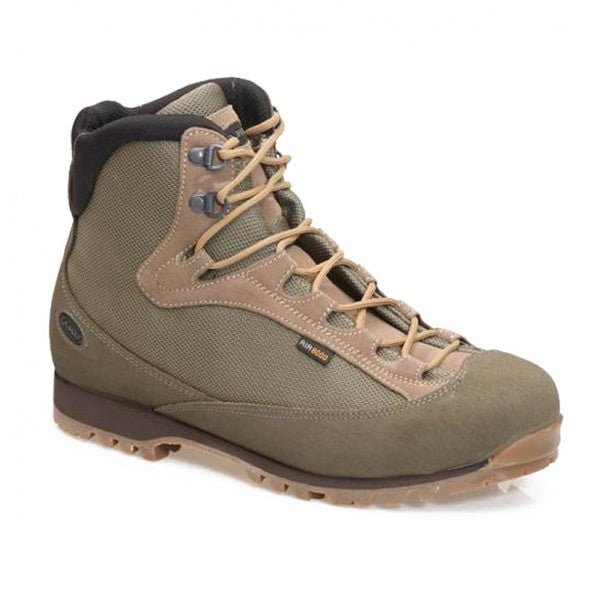

AKU Pilgrim DS

By AKU

Description

Exclusive to Platatac (in Australia).

Developed from the hugely successful AKU Navy Seal the Pilgrim DS offers the same unparalleled breathability and quick drying, but with added impact absorption. Increased ankle height provides stability and support and a new sole unit with a deeper tread provides traction on varying terrain.

The Pilgrim DS is perfect for demanding duties in hot climates, where ultimate breathability and quick drying are critical. The uppers are made from Air 8000, making the Pilgrim DS 11 times more breathable than traditionally constructed fabric boots.

Developed with a new last for improved forefoot width and secure heel grip the Pilgrim DS is definitely capable of long tours and extended duties. The heavier duty Vibram outsole features deeper lugs for improved grip on a variety of terrain and has a built in rocker to produce a stable and progressive walking platform.

A hugely capable boot designed for purpose and with the addition of the Pilgrim GTX to the range you can have boots suitable for hot, dry, temperate and wet conditions with assurance of a consistent fit wherever you are operating.

INTERNAL MIDSOLE SYSTEM (IMS)

IMS is designed to reduce the risk of injury and increase stability when load carrying.

IMS uses an anatomically shaped 3D midsole that mimics the natural foot shape. Conventional midsoles are flat and offer no structural support to the foot, only dictating the stiffness of the boot. With an IMS 3D midsole the foot is cradled in a relaxed position therefore reducing fatigue and minimising slippage.

Above the IMS midsole is a 3mm layer of high density EVA. This protects the user from loading forces particularly when carrying heavy packs. It also provides a layer of protective support for foot rather than it resting on a hard material.

Below the IMS midsole is a thicker layer of 5mm (under the forefoot) and 17mm (under the heel) high density EVA which absorbs impact forces from the ground.

IMS 3D anatomical midsoles remove the need to “upgrade” boots with off the shelf supports and insoles.

AIR 8000

A high wicking lining fabric is laminated to the tough 3D woven nylon face fabric using a net glue. Traditional manufacturing uses a complete layer of glue to stick the inner and outer layers together, but this restricts breathability. The Pilgrim DS and Pilgrim GTX use a net glue, which minimizes this restriction and allows for superior breathability.

The face fabric is a tough 3D woven nylon. Constructed with a raised and increased surface area providing far greater abrasion resistance.

The combination of these technologies allows the Pilgrim DS to breathe 11 times better than any of its competitors, and the Pilgrim GTX to have 30% more breathability than conventional Gore-Tex lined boots

VIBRAM SOLE

Pilgrim uses a Vibram sole which was selected for its more stable platform, deep self-cleaning lugs and positive heel brake for increased traction when descending.